Advanced Industrial Reactor Monitoring System

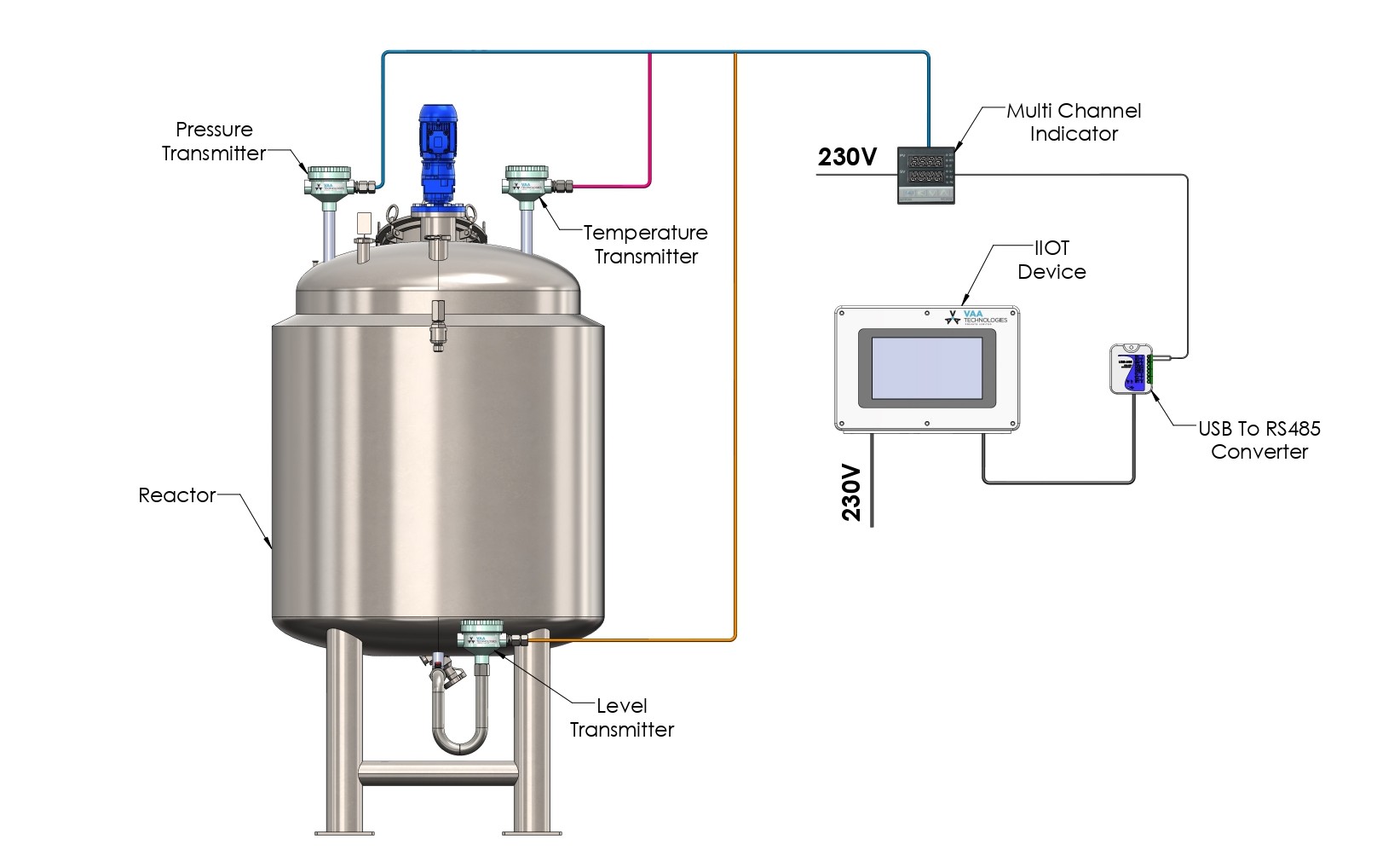

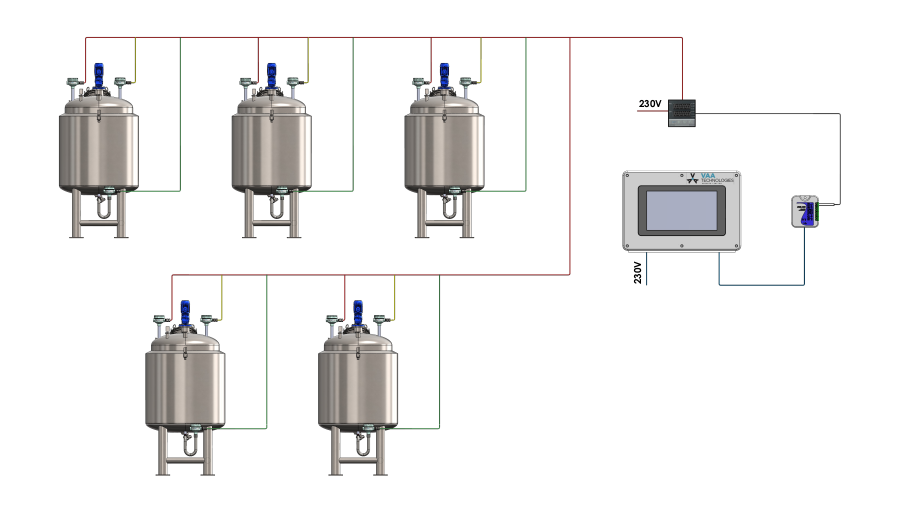

The Reactor Monitoring System for Chemical and Pharmaceutical Industries is a cutting-edge technology designed to revolutionize reactor monitoring and control. A comprehensive solution for maintaining optimal conditions within a reactor, including temperature, pressure, pH level, and agitation speed. Using the Reactor Monitoring System, chemical and pharmaceutical industries can achieve unprecedented precision and efficiency. With this advanced technology, reactions and processes take place under ideal conditions, maximizing productivity and minimizing errors.

The Reactor Monitoring System for Chemical and Pharmaceutical Industries is a game-changer in the field of reactor control. By offering real-time monitoring and regulation of temperature, pressure, pH level, and agitation speed, this advanced technology guarantees optimal conditions for chemical reactions and pharmaceutical processes. With increased precision and efficiency, industries can now achieve higher yields, improved product quality, and enhanced safety in their operations. Experience the future of reactor monitoring with our state-of-the-art system.